Common terms used in the 3D printing ecosystem

Homing#

The process of determining the location of a 3D printer nozzle in three dimensions using a reference point (the home location) is referred to as homing.

Homing should occur before every print and involves bringing the X, Y, and Z-Axis motors to pre-defined limit locations (normally via physical endstops but can also be done via sensorless homing ).

- Definition

- The process of determining the location of a 3D printer nozzle in three dimension using a reference point (home location) is referred to as “homing”.

gcodes (homing)#

- Marlin

- G28 Automated homing

- Klipper

G28operates like Marlin and facilitates automated homing of X, Y, and Z axis

Tramming#

Sometimes called ‘bed leveling’ or just ’leveling’.

Or

- Definition

- In order to adhere the hot filament from the nozzle it is essential that the distance between the nozzle and the build surface is as constant as possible.

gcodes (tramming)#

- Marlin

- Klipper

- BED_SCREWS_ADJUST Manual tramming with automated placement of nozzle on X/Y plane

- Z_TILT_ADJUST Extended gcode command to facilitate automatic tramming of at least 2 Z-steppers

- QUAD_GANTRY_LEVEL Extended gcode command when configured to facilitate automatic tramming of 4 Z-steppers

Extrusion Multiplier#

Sometimes called ‘flow multiplier’ depending on slicer in use.

The Extrusion Multiplier allows the fine-tuning of the extrusion flow rate - simply described as how much filament comes out of the nozzle.

Adjusting your EM per filament allows you to tune the amount of filament that will be extruded. Tuning this should make your parts more structually sound and give you better control over the details in your print.

Tuning EM is by filament as every filament has different properties.

- ABS/ASA may need EM adjusted from 0.8x to 0.9x

- PLA/PETG may need EM adjusted higher than 1.x

The above are not hard and fast rules.

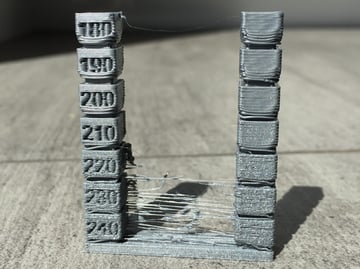

What can affect EM?

- filament type

- filament diameter

- hot-end temperature

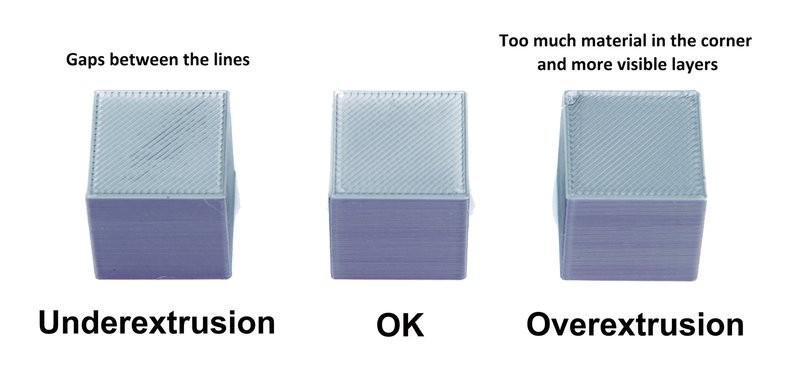

Under extrusion#

Under-extrusion is when not enough filament is extruded, which can cause prints to come out incomplete, weak, or with poor surface quality.

Over extrusion#

Over-extrusion is when too much filament is extruded which can lead to prints to coming out with incorrect dimensions, poor surface quality (blobs, zits, elephants foot), and could even cause your nozzle to grab the print pulling it away from the build plate.