Kinematics#

Image: Courtesy of All3DP

Image: Courtesy of All3DP

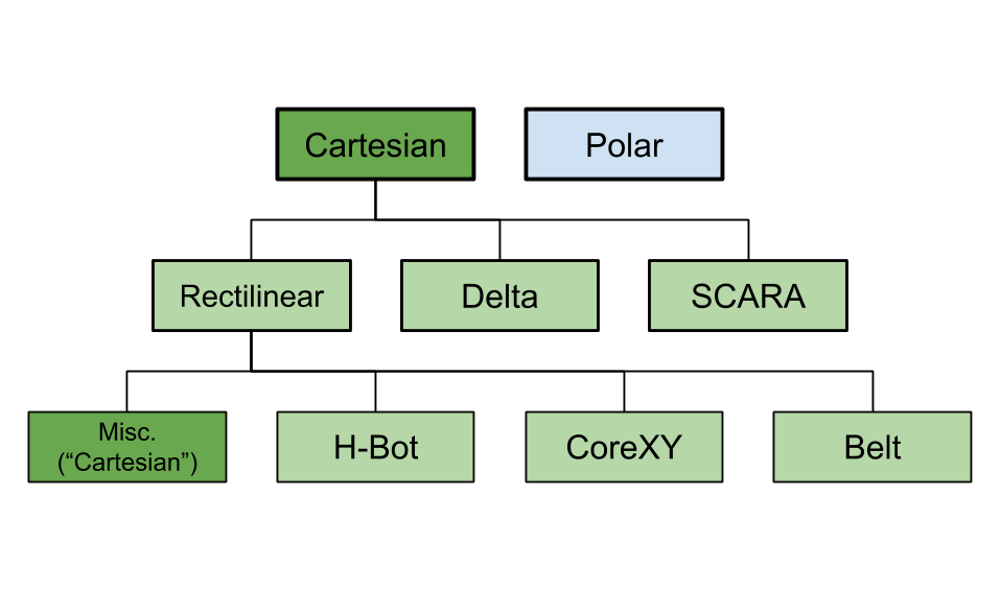

When most people think of 3D printing they are normally referring to Cartesian coordinate based printers. Inexpensive and reliable without a lot of belts or pulleys to worry about.

Cartesian#

- Description

- Motion planning, also path planning (also known as the navigation problem or the piano mover’s problem) is a computational problem to find a sequence of valid configurations that moves the object from the source to destination.

Also referred to as bedslingers or bed flingers as the Y axis moves from front to back. As the bed has a lot of mass, fast movements of the bed can create artifacts or even cause tall prints to fall over. To overcome this you can lower your acceleration and/or jerk when working with taller prints.

Our initial collection of printers are Cartesian based.

Mike’s cartesian#

- octoprint1 - Prusa MK3S+

- octoprint2 - Creality Ender 3 V2

- octoprint4 - Prusa MINI+

Jason’s cartesian#

- jam8 - ANET AM8

Stephen’s cartesian#

CoreXY#

- Description

- CoreXY printers incorporates a system of belts and pulleys to move the printhead on the XY plane. In particular, CoreXY printers use two stepper motors that move one belt each to position the printhead.

Our newest printers, and what we plan on using going forward, are CoreXY based.

Mike’s corexy#

- voron1 - Voron Trident 300 (unnammed)

- voron2 - Voron V0.1 (pocket-rocket-purpz)

- voron3 - Voron V2.4r2 300 (Ms. Green)

- voron4 - Voron V2.4r2 300 (Ms. Emerald)

- voron5 - Voron V0.1 (pocket-rocket-grayscale)

- voron6 - Voron V2.4r2 350 (Citrus Squirter)

- biggus-dickus - Prusa XL (biggus-dickus)

Jason’s corexy#

- jpr - Voron V0.1

Stephen’s corexy#

Delta#

- Description

- Delta printers support the extruder with three arms which are attached to three vertical posts arranged in a triangle. Each arm can only move vertically up and down, but by moving each arm independently the extruder is able to move in all directions.

Mike doesn’t have any plans to add Delta based printers to his collection but never say never!